The Power of IIoT in Automation

BY : Sdreatech

22-Apr-2024

The power of IIoT in automation allows real-time data gathering and exchange from industrial devices, sensors, and machines connected to the internet. This technology may make our automation processes more efficient, intelligent, and connected. In this blog, we will discuss IIoT's automation elements, benefits, drawbacks, and future trends in IIoT automation.

What is IIoT automation?

Industrial IoT automation aims to decrease manufacturing costs. This procedure improves production speed, safety, and resource and industrial analytics use in manufacturing. This goal is achieved by fully mapping out the industrial process, comprehending subprocess linkages, allocating machines to work, and automating certain process activities.

Older, fixed automated machines simply do repetitive tasks, but higher-speed, programmable machines can transfer many process decisions to high-speed controllers and operate without human intervention.

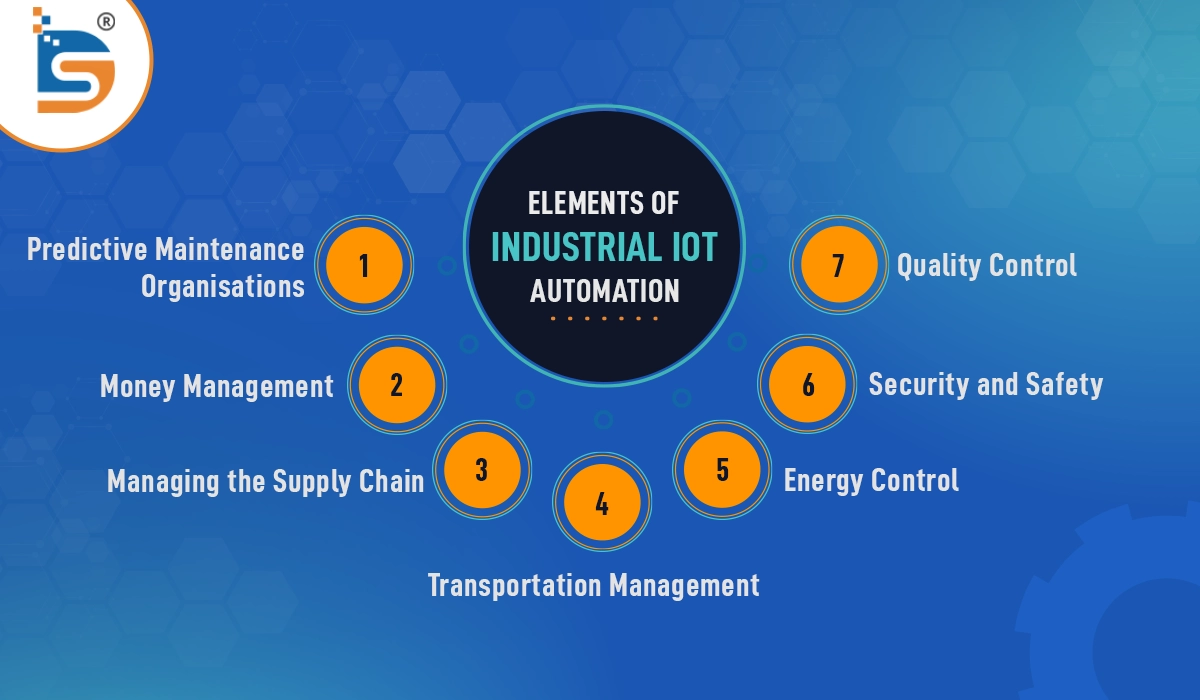

Elements of Industrial IoT Automation

With the help of the Internet of Things (IoT), businesses have been able to automate formerly manual processes, greatly improving their efficiency and output. Several industrial automation IoT solutions are helping firms optimize and succeed.

1. Predictive Maintenance Organizations

IoT industrial automation often uses predictive maintenance. They use sensors to collect real-time data from machinery and equipment to predict maintenance needs. Organizations can schedule maintenance before significant breaks, saving time and repair costs.

2. Money management

When it comes to machinery, tools, and other equipment, the IoT also helps firms keep better track of them. Businesses may track these assets' location, utilization, and performance by installing sensors, enabling more precise inventory management and increased productivity.

3. Managing the supply chain

Manufacturing and logistics depend on supply chain management. IoT technologies can monitor business supply chains in real-time to manage inventories, transports, and delivery schedules. This improves planning and decision-making, increasing supply chain efficiency.

4. Quality control

Businesses can apply real-time quality control with IoT. Companies can rapidly fix production issues by collecting and analyzing sensor data. This makes products better, eliminates waste, and saves money.

5. Energy Control

IoT also helps industrial facilities control energy. Businesses can monitor energy consumption, identify mistakes, and cut energy use with IoT sensors. This reduces costs and makes the process cleaner.

6. Security and safety

IoT can enhance safety and security in industrial facilities. IoT sensors can track workers, identify risks, and issue emergency notifications. This keeps the workers safe and keeps the building safe from any security risks.

7. Transportation Management

The IoT boosts efficiency and lowers costs for fleet-based enterprises. Businesses can optimize navigation and energy use by installing sensors on cars to detect their location, speed, and fuel consumption. This reduces costs and boosts performance.

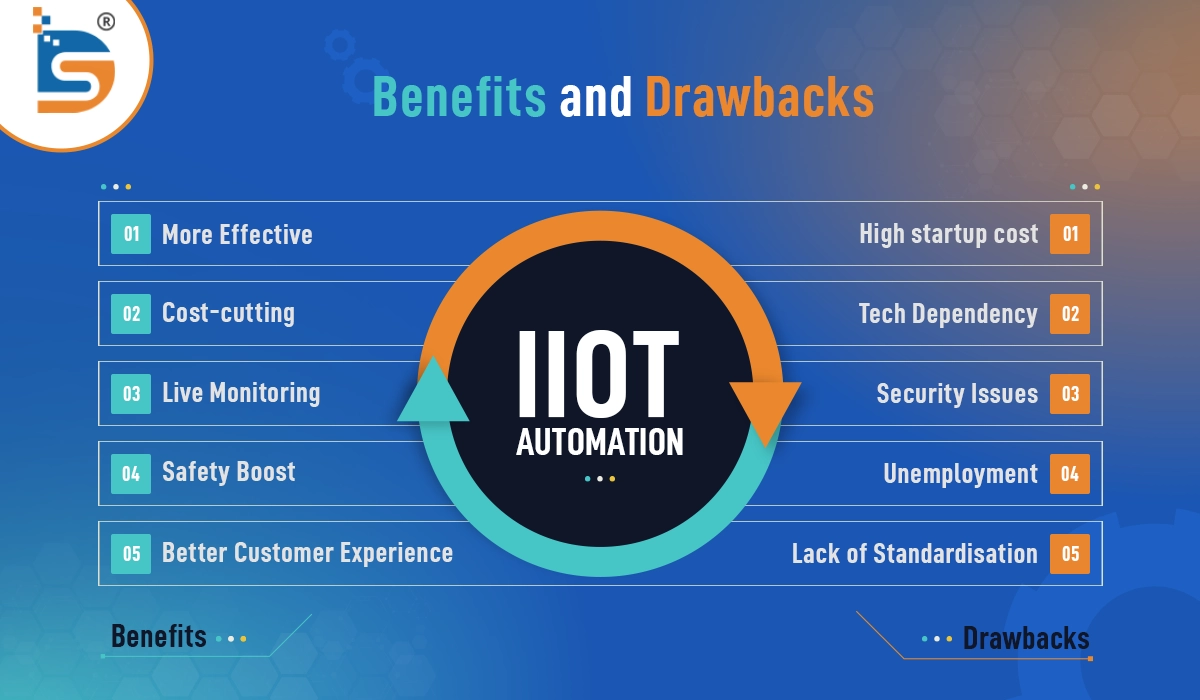

IIoT Automation Benefits and Drawbacks

Our relationship with technology and the physical environment has experienced an enormous change due to the IoT. Thanks to connected devices and sensors, the IoT has automated many industries and our daily lives. IoT devices and systems can operate automatically without human interaction. While automation provides benefits, it also has drawbacks. Let's see the IIoT automation benefits and drawbacks.

IIoT Automation Benefits

1. More Effective

Increased efficiency is one of the main benefits of automation on the Industrial Internet of Things. Sensors and connected devices automate processes, saving time and effort. This improves accuracy and consistency while saving time.

2. Cost-cutting

IIoT automation can save businesses a lot. Automation reduces labor and error expenses for companies. Automation improves resource utilization, saving organizations money.

3. Live Monitoring

IIoT automation offers real-time process and system monitoring. Businesses may collect and analyze data in real-time using connected sensors to make educated decisions and corrective measures. This boosts productivity and efficiency.

4. Safety Boost

In several businesses, IIoT automation can increase safety. Automation of dangerous operations reduces employee injury risk. In production, robots can handle hazardous substances and high temperatures.

5. Better Customer Experience

In addition, IIoT automation can improve the customer experience. Businesses can offer personalized products and services by collecting client preferences and behavior data from linked devices. Customer satisfaction and loyalty may rise.

The drawbacks of IIoT automation

1. High startup cost

High initial expenditures are a drawback of IIoT automation. Installing sensors, connected devices, and other infrastructure for automation can be expensive for small enterprises.

2. Tech Dependency

Businesses depend heavily on technology due to IIoT automation. This can hinder workflow if technical difficulties or system failures occur.

3. Security Issues

Security becomes a big issue in IoT automation as more devices connect to the internet. Because any system vulnerability can lead to cyberattacks, sensitive data can be compromised.

4. Unemployment

IIoT automation could replace human labor, creating unemployment in some industries. It can affect the economy and jobs.

5. Lack of standardization

Integrating IIoT systems might be difficult due to device and protocol non-standardization. This could cause problems with sending and receiving data, leading to bad choices. IIoT industry standards are necessary to ensure device and system integration and interoperability.

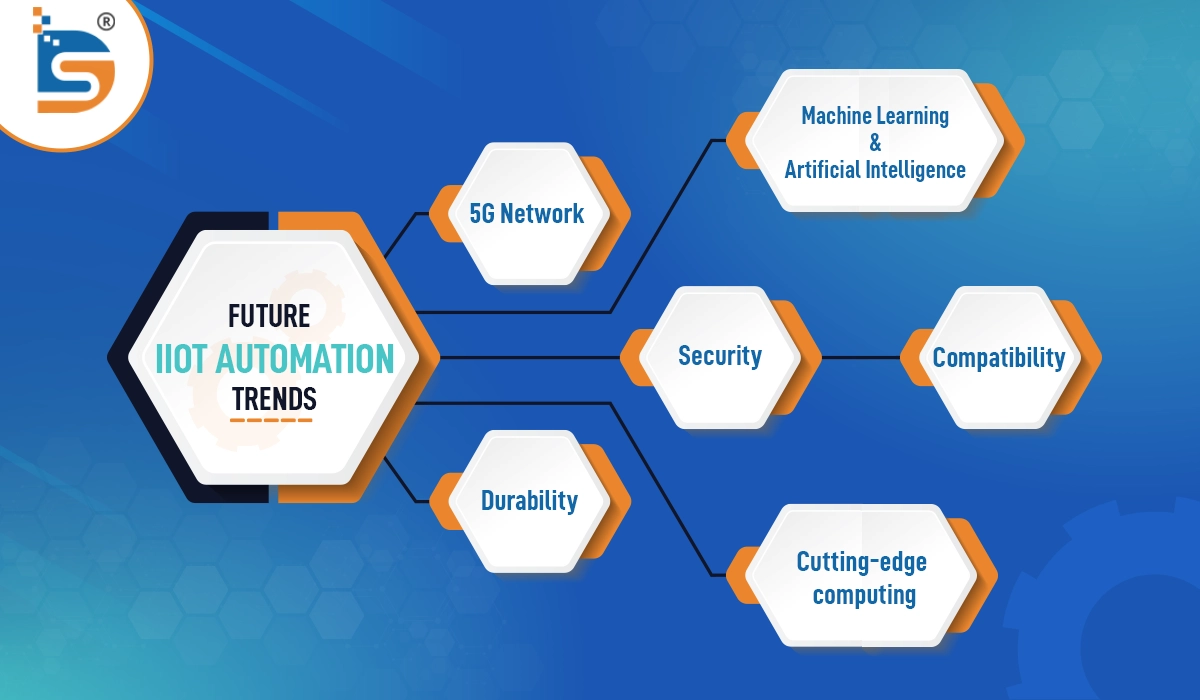

Future IIoT automation trends

The integration of IoT (Internet of Things) technology is growing as we become more connected. There are numerous IIoT applications, from smart homes to industrial automation. What is IIoT automation's future? Check out some of the biggest IIoT automation future trends.

1. Machine learning and artificial intelligence

The integration of AI and machine learning has greatly improved IoT industrial automation. These technologies can make real-time decisions based on huge amounts of IoT data. Industrial systems can foresee and avoid equipment problems, and smart houses can change temperature based on occupancy and weather. Adopting AI and machine learning will enhance the efficiency and accuracy of IoT industrial automation.

2. 5G Network

5G networks will change IoT industrial automation. 5G has better bandwidth, lower latency, and more dependable connections, making it suitable for IoT devices. IoT devices can interact and exchange data quicker and more efficiently with 5G, enabling full automation.

3. Cutting-edge computing

Processing and analyzing data closer to the point of generation at the network's edge is known as edge computing. Edge computing eliminates the need to move vast volumes of data to a central computer, thereby lowering speed and cost. IIoT devices can make fast, accurate judgments without internet access via edge computing. With more connected devices and real-time data processing and analysis, this trend will become more essential.

4. Compatibility

Compatibility will become more important as the number of industrial IoT devices and platforms increases. Compatibility refers to the interchange and communication of data between devices and systems. This will allow IoT devices from different manufacturers to work together.

5. Security

Cyberattacks rise with linked gadgets. IIoT devices are crucial to healthcare and transportation, so security is necessary. IIoT automation will utilize encryption, authentication, and access control. We must constantly update and patch IIoT devices to prevent new risks.

6. Durability

The future of IIoT automation will focus on durability as environmental concerns develop. IIoT can reduce energy use and waste by improving resource efficiency. Smart home systems change lighting and temperature based on occupancy and weather, saving energy.

Conclusion

IIoT adoption enhances business performance by reducing human involvement, leading to significant increases in productivity, profits, and worker safety. Starting with IIoT can be challenging and time-consuming, but it's undoubtedly a worthwhile investment. IIoT builds everything on demand for real-time analytics-enabled automation. Selecting the best IIoT environment is difficult since it requires flexibility and robustness. An IIoT development business can help you construct smart, flexible infrastructure.